Through our years of experience, we have optimized and partially automated the process steps from analyzing the requirements to servicing our solutions.

After an on-site visit and detailed capture of your ideas and specifications, we develop a concept, a detailed design, and manufacture your custom system. Our team is, of course, available for any questions or requests even after the system is operational.

On the following pages, we would like to inform you about the exact steps of our workflow. If you need further information, please feel free to contact us.

As the basis for comprehensive process optimization, we work with you to create current state and requirements analyses. In addition to redesigning entire systems, we also identify improvement potentials in existing manufacturing processes.

Upon request, we can provide a cost/benefit analysis of our solution approach.

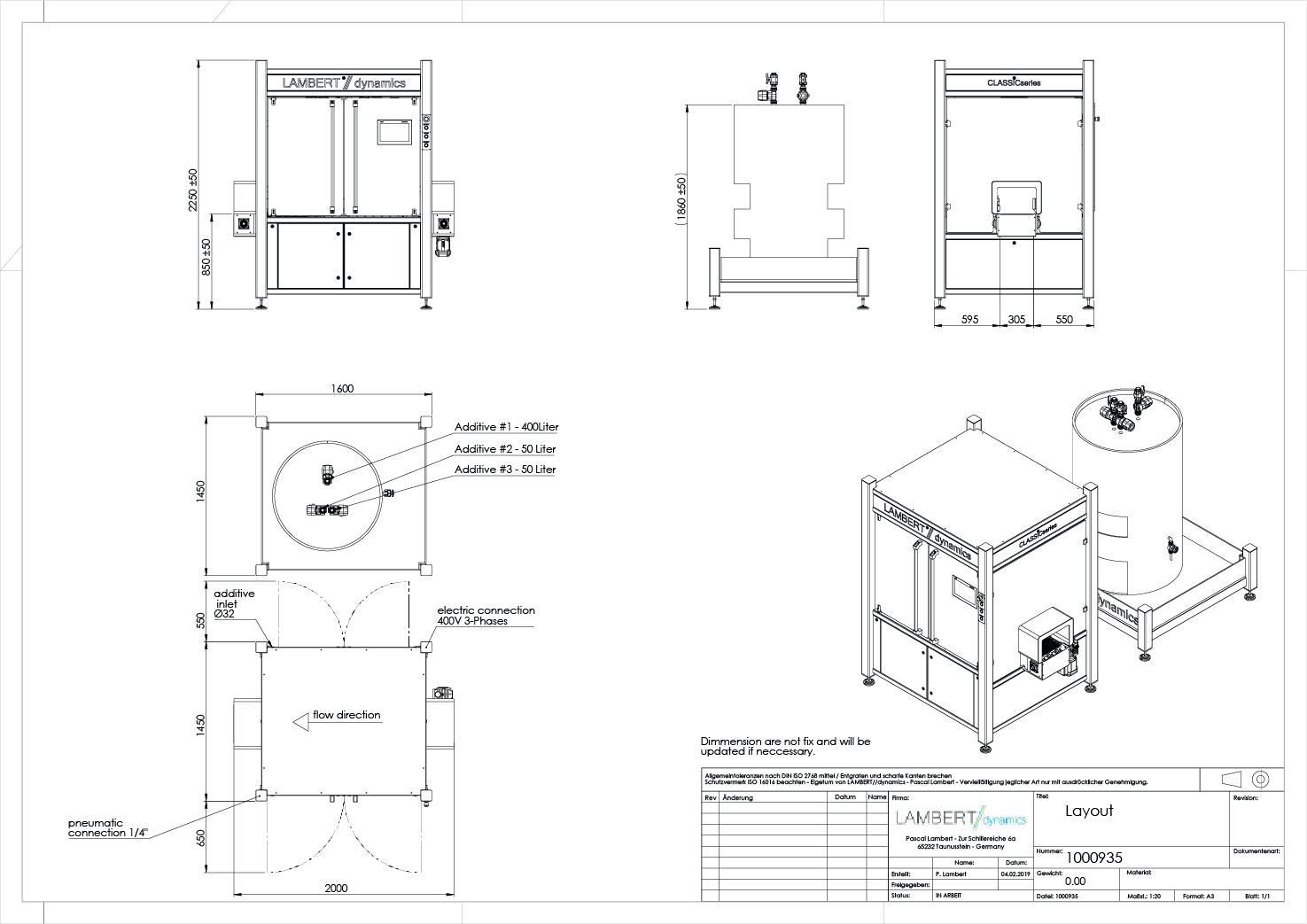

Based on the insights gained from your requirements, we develop a concept, which we detail and visualize using the latest CAD technology, and present as part of a quotation. During the conceptualization, we compare and evaluate various solutions to select the best option for you.

In addition to mechanical design, we also handle the software and hardware planning of the control components. This includes electrical circuit diagrams, pneumatic circuit diagrams, and supply circuit diagrams for fluid control.

We use our own ICON library for visualizing and operating our systems, enabling innovative user interfaces.

We maintain close partnerships with our local suppliers and have access to a range of manufacturing processes.

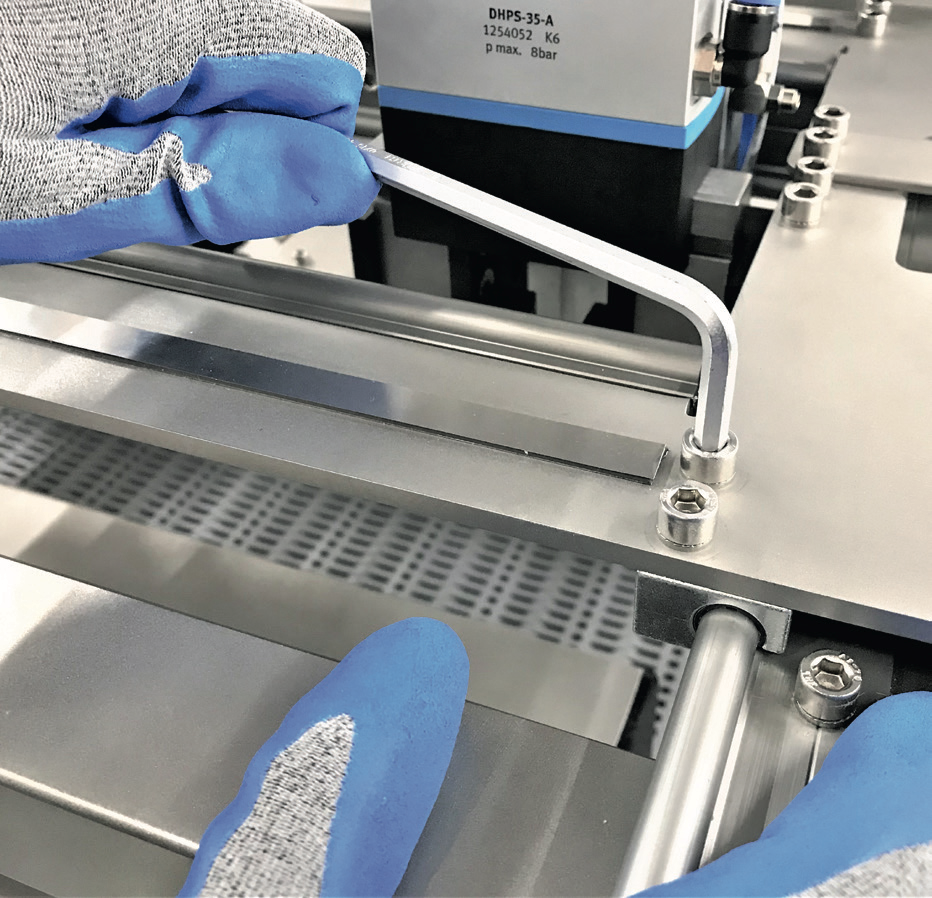

The assembly and commissioning of individual components, as well as control cabinet construction, take place at our facility in Taunusstein.

Before the delivery of a system, it undergoes several internal inspections and test runs to ensure a quick and smooth commissioning on-site at your location.

Assembly, installation, and process integration are carried out effectively and efficiently by our qualified personnel.

Our global experience with commissioning custom machines enables our team to work efficiently even under high time pressure and challenging conditions.

Training for operators and maintenance staff is also included as part of the commissioning process, ensuring a smooth transition to working with a new system.

We are happy to assist you if you need the help of a specialist. Our service can be reached by phone or can connect with you via a secure data connection through Remote Access. We ensure that the design of our systems guarantees minimal wear and tear.

Should it be necessary to replace spare parts, we promise prompt processing and shipping of the required components.

Send us a brief message or give us a call. We are happy to review your requirements and assist you with our expertise.

We look forward to hearing from you!